Studs

Studs

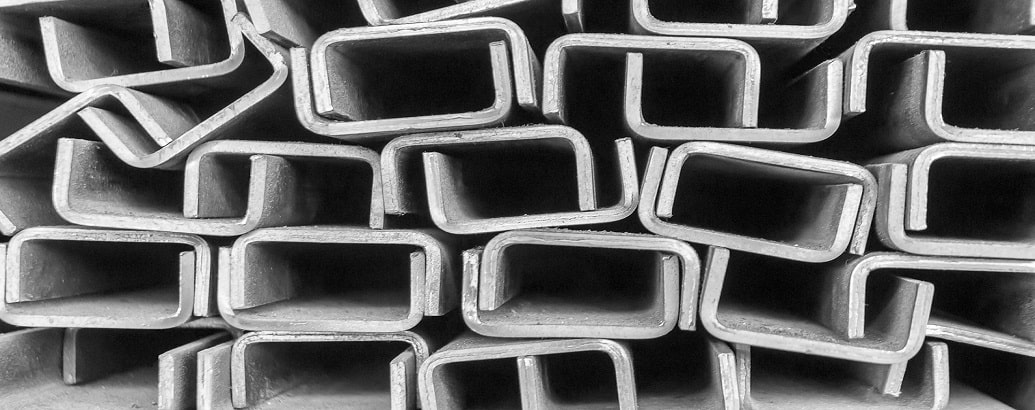

Studs are one of the most popular and widely used profiles in industry and construction due to their suitable geometric shape. Gutters are one of the game profiles that are widely used in the construction of foundations and structures. In this article, we will tell you what studs are. Industrial and construction studs are a profile that is geometrically similar to the English U. The cross-sectional area of the gutter consists of one core horizontally and two wings vertically. Note that the internal angles of the gutter profile cross section are round.

What is a stud?

Gutter profile with steel section, which is made of rolled carbon steel billets and its cross-sectional shape consists of a horizontal core and two vertical wings in the shape of the English letter U, which has a rounded curvature in the inner corners of the cross-section. This profile is in the group of open profiles and is one of the industrial and construction profiles that are produced with open section.

Gutter specifications

It is usually supplied in the form of a branch and sometimes cut into small pieces called studs. The studs have two characteristics: wing length and wing thickness. They are called and are classified according to wing length and thickness and in millimeters. Normally, studs with parallel wings are also used in construction, but there are also non-parallel or conical wing types that have their own applications. In the past, the process of producing studs was by pressing, in which a steel sheet was bent twice the width of the sheet and formed gutters perpendicular to each other, but now it is produced in situ (fabric) from the very beginning in the form of studs. To be.

Gutter applications

The shape of the studs provides a superior structure for construction projects, and this product is ideal for frames and foundations used in machinery, truck skeletons, frames, architectural restorations, marine structures, buildings, construction equipment, etc. It is very suitable. Gutter profiles are classified into "C" and "U" types depending on their application. Therefore, there are two dimensional standards, UPE and UPN. UPE is used for C studs with parallel wings and UPN is used for U studs with tapered wings. The appearance of this product has led to their use in a variety of applications. These costs include the following:

machinery

Framework

Restoration of architectural buildings

Building

Construction equipment

Marine organization

Application in beams and building columns

Build trusses

Truck skeleton

Construction equipment

Types of studs

It is generally in the following three ways

European

European counterpart

Structural

European studs (UNP)

UNP or European studs is one of the stud profiles in the country that weighs more than other studs in the market. Usually more UNP studs in large projects or industrial projects that need this type of UNP studs It is used because UNP studs are thicker and therefore weigh more.

Single or pair in windbreaks

Single and double in the beams

Paired and canned in columns

In the form of pairs in the construction of trusses

Types of studs in terms of weight

Types of studs in terms of weight are as follows:

Heavy

Heavy studs in terms of weight and defined dimensions are exactly equal to the Stahl table. In other words, this product is produced based on the sizes recorded in the calculation table. European studs and European equivalent weight are called heavy studs.

Style

That is, gutters that weigh less than the weight defined in the standard Stahl table. Construction studs can be light and heavy, but are generally lighter than the above two types.

Types of studs in terms of production process

Gutters can be divided into 3 general categories in terms of production process, as follows:

pressed

Fabric

Hot and cold rolling

pressed

It is formed in the form of a press and its production is done by a roll forming machine, and finally the final product is U-shaped.

Fabric

Which has been the same U shape from the beginning; But it is produced with sharp and vertical internal angles.

Hot and cold rolling

It is a galvanized product in which alloys such as steel and zinc are used and increase their life. Percentage of using different alloys are effective in determining the price and weight of studs and its production is done through hot and cold rolling.

Types of studs in terms of appearance

Simple

Mesh

1. Simple

It is mostly used in the design of air conditioners and hot sheet is used to make it in the construction and industrial industries. But in other cases, if they want to provide the galvanized type, according to the various needs, this can be done both hot and cold. Regarding the size, it should be said that this type of profiles in five dimensions. 8, 10, 12, 14 and 16 are available. The height of this type of studs can be changed between 30 to 400 mm, which naturally is not ineffective in determining the price of studs.

2.Network

According to the need and how to use in their structure, galvanized sheets (both hot and cold) have been used and are mostly used in shelving, light buildings and ...

Introducing famous studs

Aluminum studs

Among the famous applications of studs, due to their high strength and durability and stability against rust, can be: their use in building facades, trailer or truck floors, metal molds, door and window construction (which These types of profiles have two grooves on both sides of the cross section) and decoration. To implement modern designs in building facades, we can name aluminum studs. In fact, these infrastructures, which are the main cornerstone for designing the facades of buildings, are known as structures and include different and varied sections according to the type of facade covering and their installation system.

To produce high quality aluminum studs, it is necessary to use special alloys in their compositions and to perform precise engineering calculations for their heat treatment. This type is produced according to American standards and is considered a part of 6000 series. To be. Aluminum studs have high resistance to corrosion and heat and due to the fact that they are light, they also have high weldability. Regarding the dimensions of this product, it should be said that the cross-sectional size of this type of profile can be from 8 * 8 to 100 * 100 mm variable.

Steel studs

Regarding this type of profile, it should be said that it is one of the most widely used studs in industry and construction and is available and used as a U-shaped cross section. Regarding the types of steel studs, it should be said that: This type of profile is available in two forms. Simple and mesh for consumers.

Measurement

The criterion for naming is the height of its wings and this number is expressed in centimeters. That is, if the height of the wings of a stud is 8 cm, it is known as stud 8. And they have different sections, which we refer to below:

UNP 30 × 15, UNP 30, UNP 40 × 20, UNP 40, UNP 50 × 25, UNP 50, UNP 60

UNP 65, UNP 80, UNP 100, UNP 120, UNP 140, UNP 160, UNP 180

UNP 200, UNP 220, UNP 240, UNP 260, UNP 280, UNP 300, UNP 320

UNP 350, UNP 380, UNP 400